Introduction:

The single-stage coal gasifier is a special equipment that uses coal or coke as raw material, air and water vapor as gasifying agents, and produces mixed gas through oxidation and reduction reactions in a fixed bed.

Coal gasifier can be widely used in various types of industrial kilns that burn coal gas or replace the original coal in metallurgy, machinery, chemical industry, building materials, refractory materials, ceramics and other industries, such as heating, baking, annealing, drying, heat treatment, melting and tunnel, push plate, roller, downdraft and other kilns.

Main Equipment:

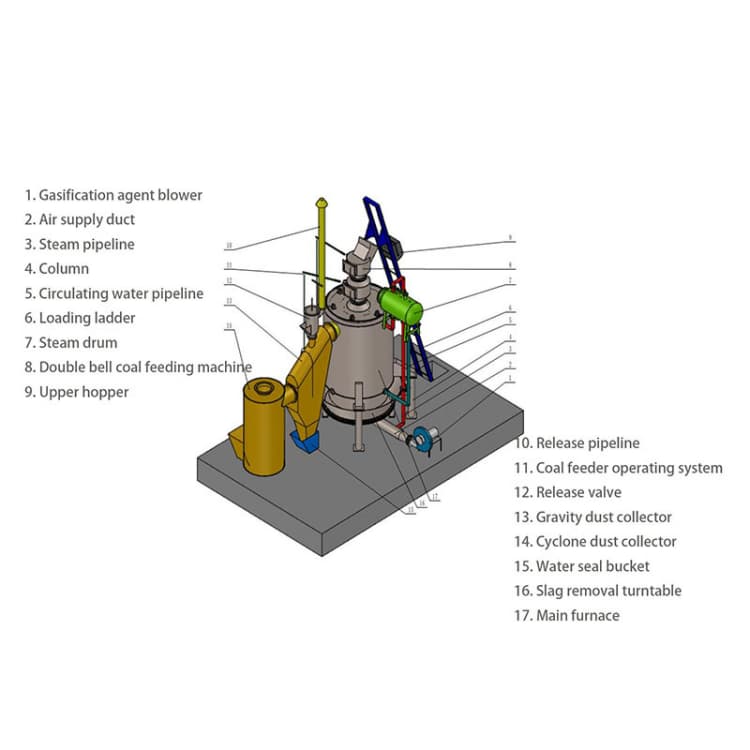

Single stage gas producer is mainly composed of single stage gas producer, cyclone dust collector, gravity dust collector, drum, ash hopper and other equipment.

Structural features:

1. Coal charging section: the multi-tube coal distribution device is used to ensure that the coal entering the furnace is evenly distributed in the furnace. This section is also equipped with a practical and reliable coal level detector, which cooperates with the stoker to complete automatic coal feeding.

2. Dry distillation section: There are two types of furnace linings to choose from. One is the refractory brick lining, which has a fast construction speed and a short furnace baking time; the other is unshaped integral casting furnace lining, which has the characteristics of high heat transfer efficiency, good distillation effect, and easy maintenance, and its performance is better than the refractory brick lining.

3. Gasification Section: It adopts a water jacket structure and produces self-produced steam for gasification of the furnace bottom.

4. Coal filling mechanism: It adopts the advanced upper drum, middle plug-in plate and lower bell-shaped coal feeding mechanism, which has the characteristics of simple operation, convenient maintenance and good air tightness.

5. Cleaning mechanism: ratchet, pawl and hydraulic double-sided ash removal are adopted, and the large ash knife adopts the self-designed plow-type ash removal knife, which has stable and reliable transmission and smooth ash removal.

Application:

The main components of the gas produced by the single-stage gasifier are carbon monoxide, hydrogen, and methane. The gas can be used for general industrial thermal processing, such as ore drying, ceramic firing, boilers, kilns, and various industrial thermal processing furnaces.

Parameter:

| Type | Φ0.8m | Φ1.0m | Φ1.3m | Φ1.5m | Φ1.8m | Φ2.0m | Φ2.4m | Φ2.6m | Φ3.0m | Φ3.2m | Φ3.4m |

| Furnace inner diameter(mm) | 800 | 1000 | 1300 | 1500 | 1800 | 2000 | 2400 | 2600 | 3000 | 3200 | 3400 |

| Furnace cross-sectional area(m2) | 0.5 | 0.785 | 1.326 | 1.77 | 2.54 | 3.14 | 4.52 | 5.31 | 7.07 | 8.04 | 9.07 |

| Applicable coal type | Anthracite, bituminous coal | ||||||||||

| Coal particle size(mm) | 20~50 | ||||||||||

| Coal consumption(kg/h) | ≤50 | ≤120 | ≤180 | ≤250 | ≤400 | ≤550 | ≤700 | ≤1000 | ≤1500 | ≤2000 | ≤2600 |

| Gas production(m3/h) | ≤170 | ≤420 | ≤650 | ≤900 | ≤1400 | ≤1920 | ≤2500 | ≤3500 | ≤5300 | ≤7000 | ≤9000 |

| Gas calorific value(KJ/m3) | 5020~6060 | ||||||||||

| Air consumption(m3/kg) | 2.2-2.8 | ||||||||||

| Steam consumption(m3/kg) | 0.3~0.5 | ||||||||||

| Gas outlet temperature(℃) | 400~550 | ||||||||||

| Saturated air temperature(℃) | 50~65 | ||||||||||