Introduction:

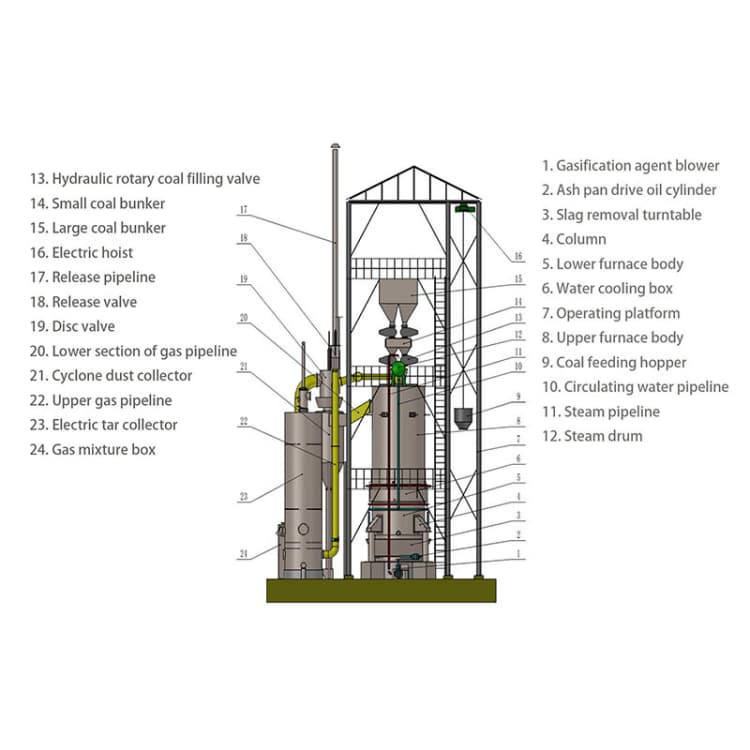

The two-stage coal gasifier is composed of upper-stage gas and lower-stage gas. It is a system project, that is, the advantages of the two-stage furnace are inseparable from the various elements of the system, such as coal preparation, gasification, purification, pressurization, environmental protection control and public facilities. Its process flow is designed overall according to the user's different requirements for fuel and quality requirements.

The gas produced by the two-stage coal gas producer can be widely used in industrial thermal processing, suitable for steel forging, ceramic firing, ore drying, and various heat treatment furnaces.

Working principle:

Qualified raw coal is lifted by electric hoist to the coal storage bunker in the main plant, and then added into the furnace through double-drum hydraulic stoker. The coal is heated and distilled by the gas from the gasification section. The semi-coke coal after distillation reacts with the gasifying agent (air, steam) in the gasification section. The gas generated in the gasification section is divided into two parts. One part is discharged from the gas outlet of the lower section of the two-section furnace through the cyclone dust collector, and the other part goes up through the central pipe to mix with the distillation gas and is discharged from the upper gas outlet.

The coal gas at the outlet of the lower section enters the forced air cooler after being cooled and dusted by the cyclone dust collector, where it continues to be dusted and cooled, and then enters the intercooler for further cooling. The coal gas at the outlet of the upper section enters the electric tar precipitator for decoking, and then directly enters the intercooler to mix with the coal gas at the lower section, where it is cooled during mixing. After mixing, the coal gas enters the electric light oil catcher to remove light oil, and then is pressurized by the booster fan and sent to the water mist drip collector for dehydration before being sent to the user.

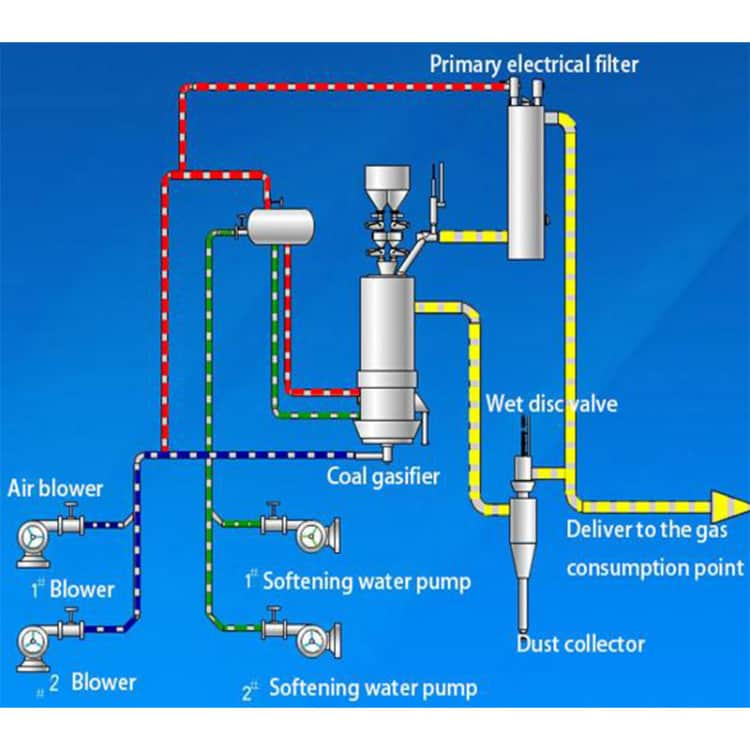

Flow chart:

Advantage:

1. The calorific value of coal gas is higher than single stage gas producer.

2. The thermal efficiency is 10% higher than single stage gas producer.

3. The cooling of coal gas can be done by indirect cooling. The circulating water quality of coal gas cooling is clean, the amount of condensed water of the phenol-containing dry distillation coal gas is small, and it is easy to handle to meet the standards, which is beneficial to the improvement of environmental protection.

4. After the coal gas is detarred, it can be transported to 300-400 meters away without heating.

5. The coal gas is cooled and detarred to remove impurities, and can be transported over long distances if pressurized.

6. After desulfurization, cold clean desulfurized coal gas can be produced for residents to use. Its derived processes, such as cold and hot coal gas processes, can produce two types of coal gas with different calorific values ??and deliver them to users respectively.

7. Wide applicability of coal: lean coal, non-sticky bituminous coal, long bituminous coal, bituminous coal with an expansion index less than 2.5, and some lignite can be used.

Application:

The gas produced by the two-stage gasifier can be widely used in industrial thermal processing, suitable for steel forging, ceramic firing, ore drying, and various heat treatment furnaces.

Parameter:

| Type | φ1.3 | φ1.6 | Φ1.8 | φ2.0 | φ2.4 | φ2.6 | φ3.0 | φ3.2 | φ3.4 | φ3.6 |

| Furnace inner diameter(mm) | 1300 | 1600 | 1800 | 2000 | 2400 | 2600 | 3000 | 3200 | 3400 | 3600 |

| Furnace cross-sectional area(m2) | 1.32 | 2 | 2.5 | 3.14 | 4.5 | 5.31 | 7.07 | 8.04 | 9.08 | 10.8 |

| Applicable coal type | Non bonded or weakly bonded bituminous coal, anthracite coal | |||||||||

| Coal particle size(mm) | 20-40、25-50 | |||||||||

| Coal consumption(kg/h) | ≤180 | ≤300 | ≤450 | ≤550 | ≤700 | ≤1000 | ≤1500 | ≤2300 | ≤2700 | ≤3300 |

| Gas production(m3/h) | ≤630 | ≤1050 | ≤1570 | ≤1920 | ≤2500 | ≤3500 | ≤5300 | ≤8000 | ≤9500 | ≤11000 |

| Maximum furnace bottom air supply pressure KPa | 3.0 | 4.0 | 5.0 | 6.0 | 6.0 | 6.0 | 6.5 | 7.0 | 7.5 | 9.0 |

| Steam production of water jacket KG/h | 130 | 200 | 250 | 300 | 400 | 450 | 500 | 550 | 550 | 700 |

| Air consumption m3/kg | 2.0-2.5 | |||||||||

| Steam consumption(m3/kg) | 0.3-0.5 | |||||||||

| Gas calorific value KJ/m 3 | 6060-6270 | |||||||||

| Upper section 7110-7350 | ||||||||||

| Lower section 5225-5434 | ||||||||||

| Saturation temperature ℃ | 50-65 | |||||||||

| Coal addition method | Automatic | |||||||||

| Coal feeder drive device | Hydraulic drive | |||||||||

| Slag discharge method | Wet type, automatic slag discharge | |||||||||

Factory real photos: