Introduction:

Coal Gasification Power Plant refers to the use of coal to gas as fuel gas to supply power generation units, converting thermal energy into electrical energy. Coal-to-gas, or coal gasification, refers to the process of converting coal into gas fuel through a series of chemical reactions. This gas fuel mainly includes carbon monoxide (CO), hydrogen (H) and methane (CH), etc. After purification treatment, these gases meet the gas requirements for power generation units and can be supplied to power generation units. The two-stage gas generator cold gas station in Hejia, Henan is specifically designed for gas internal combustion engine power generation units. The produced gas can meet the gas demand of gas internal combustion engine power generation after multi-stage purification. This type of generator set has the characteristics of low overall investment and stable operation, and is suitable for medium and small power generation projects.

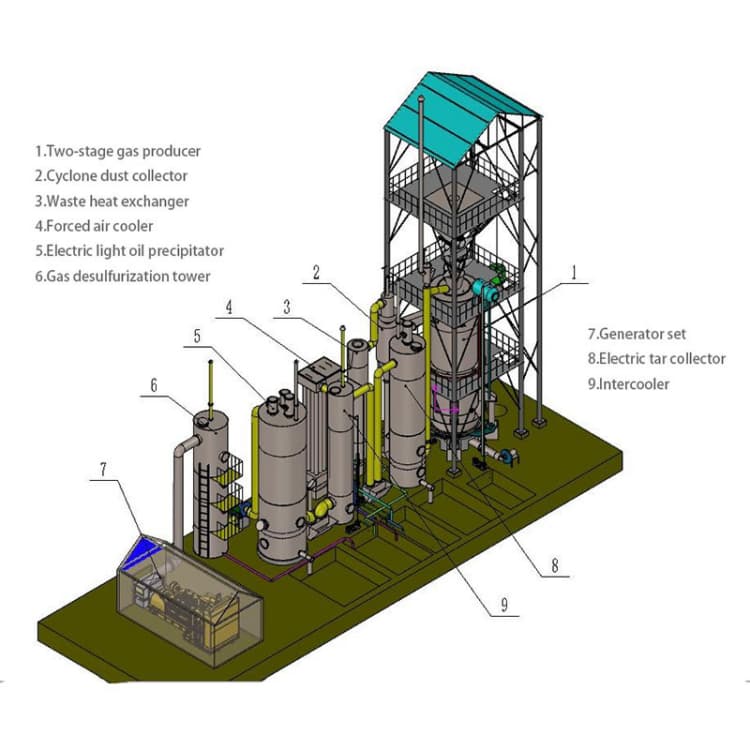

Working principle:

Qualified raw coal is lifted by electric hoist to the coal storage bunker in the main plant, and then added into the furnace through double-drum hydraulic stoker. The coal is heated and distilled by the gas from the gasification section. The semi-coke coal after distillation reacts with the gasifying agent (air, steam) in the gasification section. The gas generated in the gasification section is divided into two parts. One part is discharged from the gas outlet of the lower section of the two-section furnace through the cyclone dust collector, and the other part goes up through the central pipe to mix with the distillation gas and is discharged from the upper gas outlet.

The coal gas at the outlet of the lower section enters the forced air cooler after being cooled and dusted by the cyclone dust collector, where it continues to be dusted and cooled, and then enters the intercooler for further cooling. The coal gas at the outlet of the upper section enters the electric tar precipitator for decoking, and then directly enters the intercooler to mix with the coal gas at the lower section, where it is cooled during mixing. After mixing, the coal gas enters the electric light oil catcher to remove light oil, and then is pressurized by the booster fan and sent to the gas desulfurization tower to remove hydrogen sulfide. The gas after multi-stage dust removal, coke removal, and desulfurization is sent to the generator set through pipelines for use.

Advantage:

1. The calorific value of coal gas is higher than single stage gas producer.

2. The thermal efficiency is 10% higher than single stage gas producer.

3. Low-temperature dry distillation coal tar has low viscosity and good fluidity, and can be used as high-quality fuel or further refined and processed.

4. The cooling of coal gas can be done by indirect cooling. The circulating water quality of coal gas cooling is clean, the amount of condensed water of the phenol-containing dry distillation coal gas is small, and it is easy to handle to meet the standards, which is beneficial to the improvement of environmental protection.

5. After tar removal, the tar content of coal gas is ≤ 30mg/Nm 3.

6. The coal gas is cooled and detarred to remove impurities, with the impurity content ≤ 20mg/Nm3 and the temperature ≤ 40℃.

7. The hydrogen sulfide content of the cold clean desulfurized coal gas after desulfurization is ≤100mg/Nm3.

8. Wide applicability of coal: lean coal, non-sticky bituminous coal, long bituminous coal, bituminous coal with an expansion index less than 2.5, and some lignite can be used.

Application:

The two-stage gasifier cold gas station is specially developed and designed by Henan Hejia Company for gas internal combustion engine generator sets. The purified gas meets the gas demand of the generator set and can be used with generator sets of different powers according to the user's power generation requirements.