Introduction:

Updraft fixed biomass gasifier can gasify a variety of biomass materials such as wood chips, wood blocks, pellets, herbs, straw, etc.The flow direction of the combustible gas in this furnace type is opposite to the feeding direction of the biomass. The biomass raw material enters from the top, and as the gasification reaction proceeds, the raw material gradually moves downward. The gas generated during the gasification process flows upward and is discharged from the top gas outlet.Mature technology, stable equipment operation, efficient gas production, and adaptability to gasification of various biological materials.

Gasification principle:

The updraft fixed biomass gasification process is mainly divided into four reaction zones from top to bottom: drying zone, pyrolysis zone, reduction zone, and oxidation zone.

1.Drying zone: The free water and bound water in the biomass evaporate, and the moisture content drops from less than 20% to below 5%. The temperature in the drying zone is 30-200°C.

2.Pyrolysis zone: Biomass is cracked under oxygen-deficient conditions to produce a large amount of non-condensable combustible gases (CO, H2, CH4, etc.) and condensable tar, with a temperature range of 200-600°C.

3.Reduction zone: At 800-1000℃ and in an oxygen-deficient environment, multiple endothermic reduction reactions will occur, increasing the content of CO, H2, and CH4 in the combustible gas and improving the calorific value of the gas produced.

4.Oxidation zone: Biochar burns with supplied oxygen to produce CO2, and H2 produced by partial cracking will also react with oxygen to produce water. These two oxidation reactions will generate a lot of heat. If the oxygen supply is not enough to completely convert the char into CO2, the char will also partially produce CO, and the temperature is 800-1200℃.

Advantages and features:

1.The updraft gasifier uses insufficient air (anaerobic) to pyrolyze organic matter into combustible gas, transforming the incomplete combustion process into a complete gas combustion process, reducing the emission of solid particulate matter to below the emission standard requirements.

2.The gasification system is fully enclosed, the site is clean and beautiful, and harmless to operators.

3.Fully automatic control process, simple and convenient operation.

4.All feeding doors, slag discharge doors and inspection doors are soft-sealed. A sealing cover is provided on the top of the pyrolysis furnace to avoid gas leakage. The furnace body is well sealed to ensure the effect of oxygen-controlled pyrolysis.

5.When the pyrolysis gas spontaneously ignites, it enters the spontaneous combustion process, and the combustion-supporting device automatically stops. The entire spontaneous combustion process reaches more than 90%, greatly reducing the operating cost. It achieves the resource utilization of thermal energy, not only making the flue gas harmless, but also reducing the total amount of CO2 emissions.

Application:

1.As fuel for industrial boilers and various heating furnaces;

2.After purification, it can replace gasoline and diesel and be used for internal combustion engine power generation;

3.As domestic gas for urban residents;

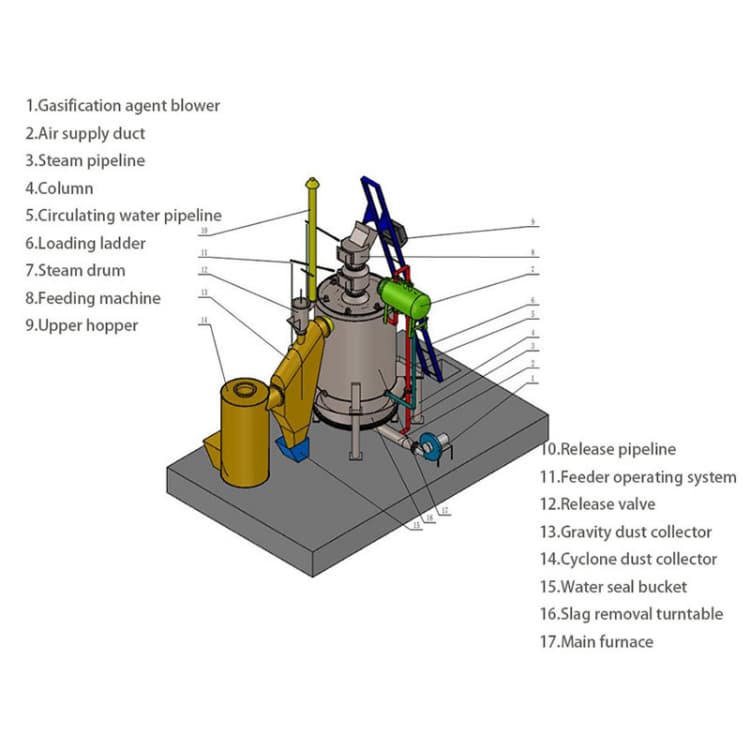

Flow chart:

Applicable raw materials:

Parameter:

| Type | Φ0.8m | Φ1.0m | Φ1.3m | Φ1.5m | Φ1.8m | Φ2.0m | Φ2.4m | Φ2.6m | Φ3.0m | Φ3.2m | Φ3.4m |

| Furnace inner diameter(mm) | 800 | 1000 | 1300 | 1500 | 1800 | 2000 | 2400 | 2600 | 3000 | 3200 | 3400 |

| Furnace cross-sectional area(m2) | 0.5 | 0.785 | 1.326 | 1.77 | 2.54 | 3.14 | 4.52 | 5.31 | 7.07 | 8.04 | 9.07 |

| Biomass consumption(kg/h) | ≤50 | ≤120 | ≤180 | ≤250 | ≤400 | ≤550 | ≤700 | ≤1000 | ≤1500 | ≤2000 | ≤2600 |

| Gas production(m3/h) | ≤170 | ≤420 | ≤650 | ≤900 | ≤1400 | ≤1920 | ≤2500 | ≤3500 | ≤5300 | ≤7000 | ≤9000 |

| Raw material | agricultural biomass materials,municipal solid waste,different biomass feedstockswood chips, corn cobs, corn stalks, wheat straw,rice husks, peanut shells, nut shells,walnut, macadamia, pistachio, coconut, hazelnut, and chestnut, bamboo chips | ||||||||||

| Gas calorific value(KJ/m3) | 4600-5000 | ||||||||||

| Air consumption (m3/kg) | 2.2-2.8 | ||||||||||

| Steam consumption(m3/kg) | 0.3~0.5 | ||||||||||

| Gas outlet temperature(℃) | 400~550 | ||||||||||

| Saturated air temperature(℃) | 50~65 | ||||||||||

Factory real photos: